Flow control valves are instruments that usually help in balancing the fluid flow or pleasure. Flow control valves accept the signal’s given out by the independent mechanism, e.g., temperature gauges and flow meters.

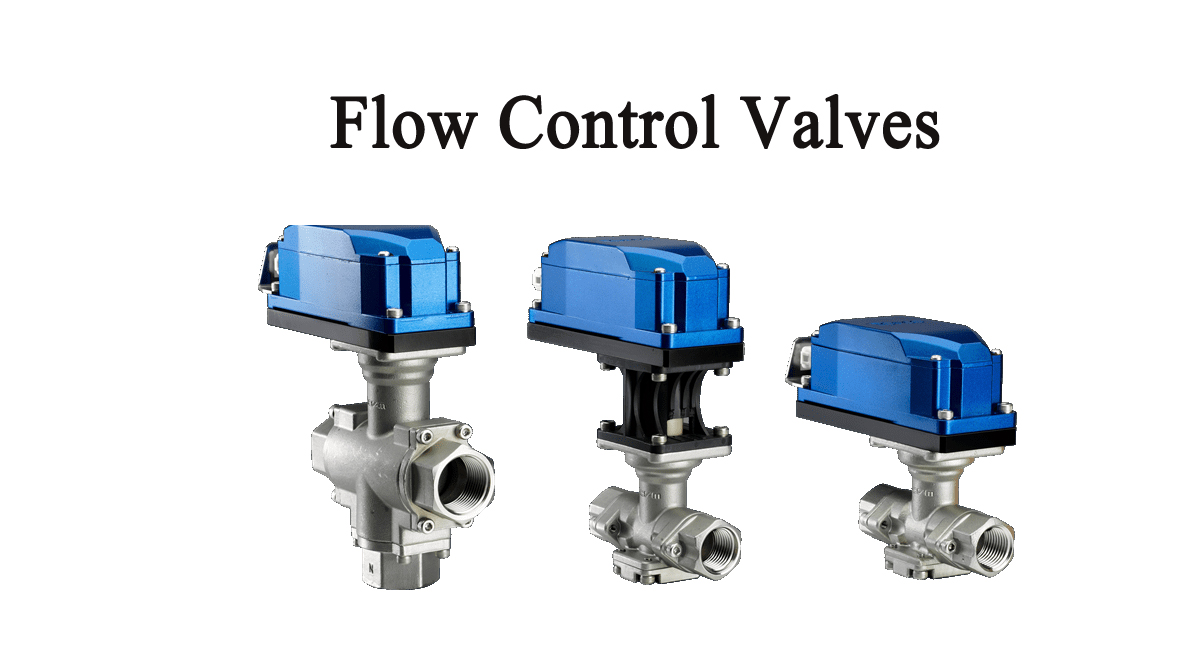

Flow control valves are available in many sizes, shapes, and designs. However, they have the same function of controlling the flow of air. A perfect example of flow control valves can be a water faucet that we always set up at our residential homes.

There are always some crucial points that you need to know about the flow control valve, especially when you want to use them. For example, you should know the various types of valves available and how they operate, and many more essential points.

If you are planning to use a flow control valve, then this article has your back. It will help you know everything about flow control valves in detail. You need to read and understand well. Let us dig deep into the types of flow control valves.

Types of flow control valves

Many different types of flow control valves have the same function of controlling the airflow. Some of the essential types include;

1. Ball valves

Ball valves are usually known to be turn-off valves. They employ a ball in starting and stopping the fluid flow downstream or upstream of the valve. The ball available in these valves does the same work as other discs in various valves.

When you turn the valve handle for opening the valve, the ball will revolve up to the point where the whole hole mounted inside the ball is at the same position as the valve body at the inlet and outlet. It will help in enhancing the fluids to move gently and pass through the valve.

If you move the ball around or rotate it to make the hole so that it is straight to the pathway of the flow, then the flow will immediately come to an end. In most cases, ball valves usually function effectively as compared to other flow control valves.

2. Gate valves

Gate valves are a type of flow control valve which you can choose for your operation. They are suitable when you need a straight line of fluid flow measurement and minor flow limitations. These valves utilize a sliding plate inside the valve body to limit and end the flow of fluids moving through the valve.

Gate valve is designed in a wedge-shaped structure. When you widely open the valve, it will fully drain inside the valve bonnet. This makes the flow movement between the valve open itself widely without any limitation. Due to this fact, there is less, pressure drops, or restriction of the flow between the valves.

You might be disadvantaged if you wanted to use gate valves on throttling volumes since it doesn’t operate in such applications. This is because it is hard to control due to the valve design and the fluid flow relying on a gate valve. This may, in turn, lead to some damages.

3. Globe valves

Globe valves are the most popular valves available. The name was derived from the rounded shape that the valve body has. Various types of flow control valves may also have this kind of shape. Due to this fact, you should know that the internal structure of the valve helps in understanding the type of valve you want to use.

The disc controls the flow in the globe valve. It would help if you connected the disc to the valve stem. You should then turn the valve site in unless the disc found in the valve seat shuts off the valve.

4. Needle valves

Needle valves usually look like globe valves in terms of size and design in their activity. However, the needle valve uses a longer tapered area at the end of the valve stem. This enhances a much smaller seating area as compared to the globe valve. Hence the needle valves can help you operate on throttling the volume of substances.

Needle valves help in controlling the flow at sensitive gauges. It may lead to destruction due to the fluid flow particles flowing with a lot of pressure. The needle valve also helps in controlling the end of the operational cycle. This is where it is usually advantageous for you to bring the movement slowly to the stopping point.

Conclusion

Flow control valves are vital in maintaining the flow portion that you need in every flow meter. This article has given you some of the essential points on the types of flow control valves that are always available. You can choose from other types of valves: butterfly valves, pinch valves, diaphragm valves, etc. Ensure that you understand a valve type well before utilizing it in your operation.